PROCESSING PLASTIC WASTE INTO ALTERNATIVE FUEL

The problem of plastic waste has become a global issue because it has been proven to pollute the environment causing damage to land, sea, and air. According to data from the Central Statistics Agency (BPS) in 2021, plastic waste in Indonesia reaches 66 million tons per year and 3.2 million tons of which is plastic waste thrown into the sea.

To resolve the waste problem, the central and regional governments have made various efforts to reduce the bad impact of plastic waste. There are three approaches taken by the government in resolving the waste problem.

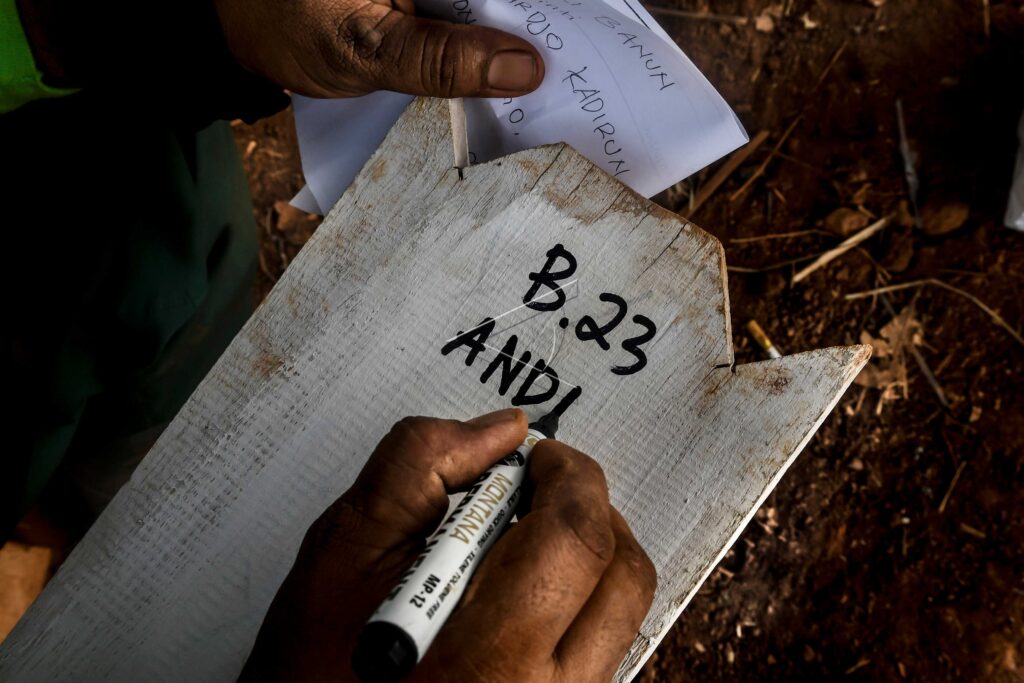

The first is a minimal waste approach by limiting and reducing plastic waste. The second is the program to recycle plastic packaging and the last is through a waste processing technology as carried by the Sidorekso Village Government, Kaliwungu, Kudus Regency, Central Java which together with local youth volunteers form a Semar Hijau waste processing group with the aim of processing plastic waste into fuel oil (BBM).

The initial step taken by the waste management group was to bring in waste processing experts to exchange knowledge about waste processing techniques on how to operate a pyrolysis waste processing tool or a machine to convert plastic waste into fuel in the form of a tube with a capacity of 100 kilograms of plastic waste.

The main processing material in the form of plastic waste is obtained from the final disposal site (TPA) which has been sorted or deposited directly by residents to the processing site.

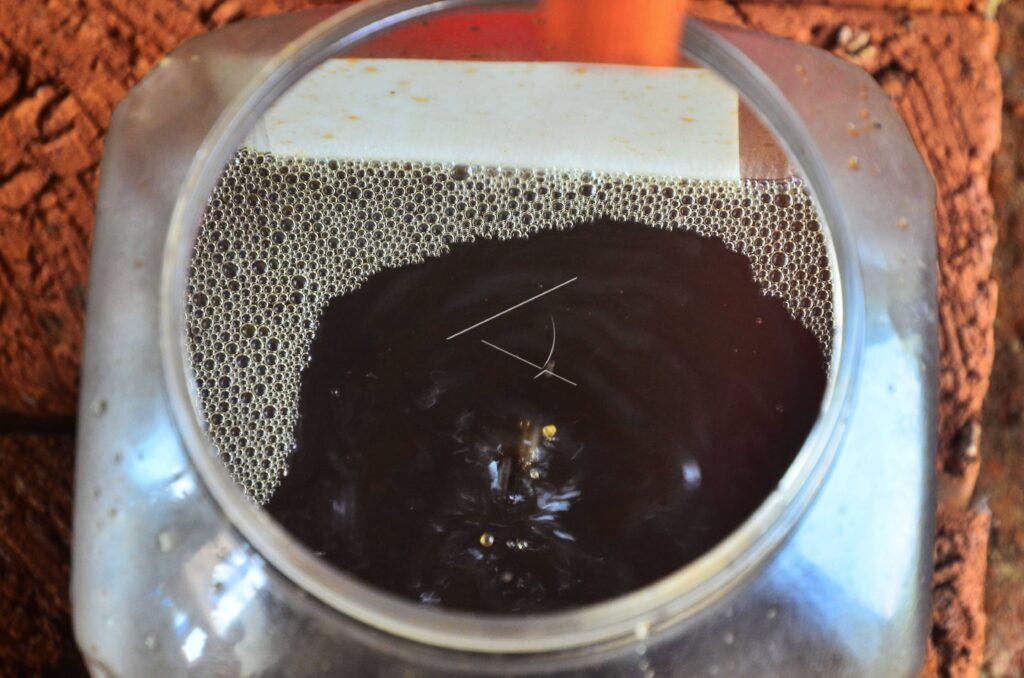

The steps for processing waste using a pyrolysis machine are, first, plastic waste is put into the reactor tube and burned at a temperature above 300 Celsius within 4-7 hours to produce plastic waste vapor which is then passed through the cooling pipe. The steam that has gone through the sublimation process then turns into a liquid and becomes crude oil which will be used as fuel for diesel, gasoline, kerosene, and thinner.

The conversion results for 100 kilograms of plastic waste can produce up to 80 liters of fuel, consisting of 50 liters of diesel equivalent and 30 liters of gasoline-equivalent.

The next step is a purification process using bentonite. The results of the purification that produce kerosene which is then sold to residents for household use and micro, small and medium enterprises (MSMEs). Meanwhile, thinners are marketed to furniture businesses, workshops, and building shops.

The Semar Hijau waste processing group which is managed through the Village-Owned Enterprises (BUMDes) using village funds, in addition to contributing to reducing plastic waste, also has benefits for the community to create a village that is healthy and free from waste as well as being energy independent.

Photo and text : Yusuf Nugroho

Editor : R Rekotomo